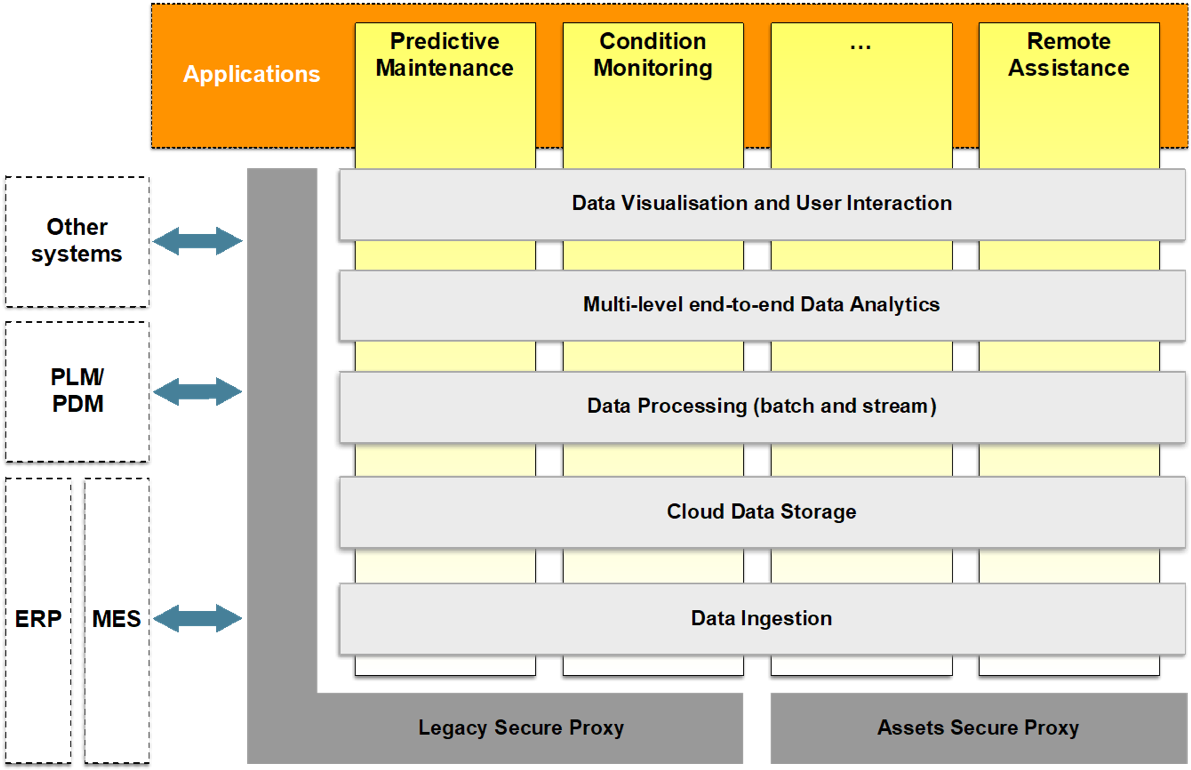

Remote factory condition monitoring and control

- Modularity/expandability

- Hardware

- Sensor interfaces

- Communication interfaces

- Hardware performance requirements

- Software

- Add/remove/configure software components

- Flexibly exchange data pre-processing modules /Algorithms

- Hardware

- Enable data pre-processing. Functionality Raw Data-Smart Data

- Access to existing control systems and monitoring infrastructure

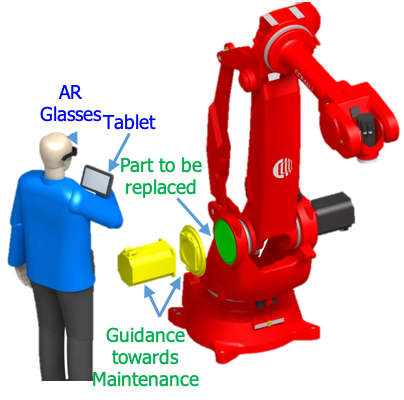

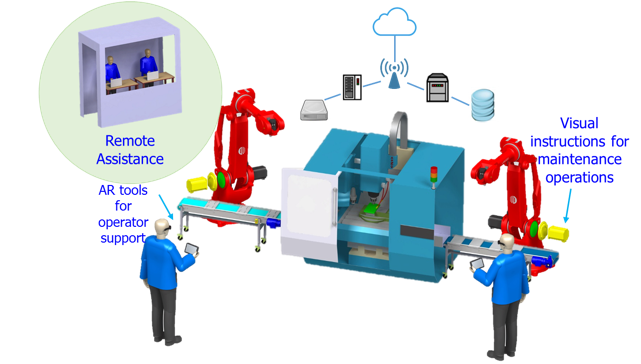

AR-base technologies for remote assistance

- Device diagnostic platform for AR content creation and delivery

UI designs for different wearable hardware

Development and adaptation of Augmented Reality (AR) based technologies for providing assistance to the maintenance personnel

Information about the status of the machinery and overall equipment within the factory

Cloud-based platform for remote diagnostics

- Managing the data remotely,

- Applying data analytics and predictive maintenance algorithms in a remote cloud

- Proposing corrective actions and guidance for maintenance in near real time and in the correct place within the factory

AI condition-based maintenance

- Data analytic algorithms for accurately predict potential failures on the equipment

- Hybrid approaches on data driven and physics-based models on the machine/equipment

- Enable planning and scheduling maintenance activities in specific timeframes without interrupting the production process plan